In recent years, crowlers have revolutionized the way beer and other beverages are packaged and enjoyed. Combining the convenience of cans with the freshness of draft beer, crowlers offer a unique solution for breweries, bars, and consumers alike.

This comprehensive guide explores everything you need to know about crowlers, including:

-

What is a crowler?

-

How do crowlers work?

-

Benefits of crowlers vs. traditional packaging

-

Best crowler machines on the market

-

How breweries and bars use crowlers

-

Environmental impact and sustainability

-

Future trends in crowler technology

By the end of this article, you’ll understand why crowlers are becoming a staple in the craft beer industry and how they can benefit businesses and consumers.

What Is a Crowler?

A crowler is a 32-ounce (946 ml) or 16-ounce (473 ml) aluminum can that is filled with draft beer (or other beverages) and sealed on-site. Unlike traditional canned beer, which is pre-packaged at a brewery, crowlers are filled fresh at the point of sale—usually at a brewery taproom, bar, or restaurant.

Key Features of Crowlers:

-

Made of aluminum (lightweight, recyclable, and blocks UV light)

-

Sealed with an airtight lid to preserve freshness

-

Typically filled using a crowler machine

-

Great for takeaway beer, limited releases, and special events

How Do Crowlers Work?

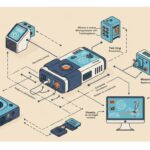

Crowlers are filled and sealed using a crowler machine, which functions similarly to a can seamer. Here’s how the process works:

-

A clean, empty can is placed under the draft tap.

-

Beer is poured directly from the tap into the can.

-

The lid is placed on top, and the crowler machine seals it airtight.

-

The crowler is labeled with beer details (name, ABV, date, etc.).

This on-demand packaging ensures maximum freshness, making crowlers a favorite among craft beer enthusiasts.

Crowlers vs. Growlers: Which Is Better?

For years, glass growlers (64-ounce jugs) were the standard for takeaway draft beer. However, crowlers have gained popularity due to several advantages:

| Feature | Crowler | Growler |

|---|---|---|

| Material | Aluminum (light, durable) | Glass (heavy, breakable) |

| Size | 32 oz or 16 oz (more portable) | Typically 64 oz (bulkier) |

| Freshness | Airtight seal (longer shelf life) | Screw-top or cap (less secure) |

| UV Protection | Blocks light completely | Glass can let light in (skunks beer) |

| Recyclability | Fully recyclable | Glass is recyclable but heavier |

| Portability | Easy to transport, no leaks | Risk of breaking if dropped |

Why Crowlers Are Winning:

Better freshness retention (less oxidation)

More convenient for consumers (smaller size, no breakage risk)

Easier for businesses to manage (no returns or cleaning needed)

Best Crowler Machines in 2024

If you’re a brewery, bar, or homebrew enthusiast looking to package beer in crowlers, you’ll need a reliable crowler machine. Here are the top models available today:

1. Oktober Seamer (Manual Crowler Machine)

-

Best for small breweries and bars

-

Manual operation (no electricity needed)

-

Durable stainless steel construction

2. Cask ACS Automatic Crowler System

-

Fully automated filling & seaming

-

High-speed production (up to 15 crowlers per minute)

-

Ideal for large breweries with high demand

3. Goose Canning Machine (Semi-Automatic)

-

Affordable mid-range option

-

Easy to use with minimal training

-

Compact design for small spaces

4. American Canning Crowler Seamer

-

Commercial-grade durability

-

Used by major craft breweries

-

Consistent, leak-proof seals

How Breweries & Bars Use Crowlers

Crowler have become a game-changer for businesses in the beverage industry. Here’s how they’re being used:

1. Taproom Sales

-

Allows breweries to sell fresh draft beer to-go

-

Great for limited-edition releases

2. Bars & Restaurants

-

Lets customers take home unfinished draft beer

-

Reduces waste from unsold kegs

3. Events & Festivals

-

Easy way to serve fresh beer without glass restrictions

-

Faster than filling growlers

4. Homebrewers & Small Batches

-

Affordable way to package experimental brews

-

No need for expensive bottling lines

Environmental Impact: Are Crowlers Sustainable?

One of the biggest advantages of crowlers is their eco-friendly nature:

100% recyclable aluminum (unlike plastic growlers)

Lighter than glass, reducing shipping emissions

No need for cleaning/reuse (eliminates water and energy waste from washing growlers)

However, critics argue that single-use cans generate more waste than reusable growlers. The best solution? Recycling programs and reusable crowler initiatives are emerging to address this concern.

The Future of Crowlers

As the craft beer industry evolves, crowler are expected to grow in popularity due to:

Expansion into other beverages (cocktails, cold brew, kombucha)

Smart labeling technology (QR codes for freshness tracking)

More sustainable materials (biodegradable liners)

With big breweries and small craft producers adopting crowler, they’re set to become a standard packaging option worldwide.